Ukusetyenzwa kwe-SMT yinkqubo entsonkothileyo ebandakanya amanyathelo okucubungula amaninzi, ezinye iinjineli zinokuthengisa amacandelo e-SMD ngokwawo, kodwa ndiya kukuxelela ukuba kutheni kufuneka iphathwe kuphela ngabasebenzi abaqeqeshiweyo.

Okokuqala, yintoni inkqubo ye-welding ye-SMT?

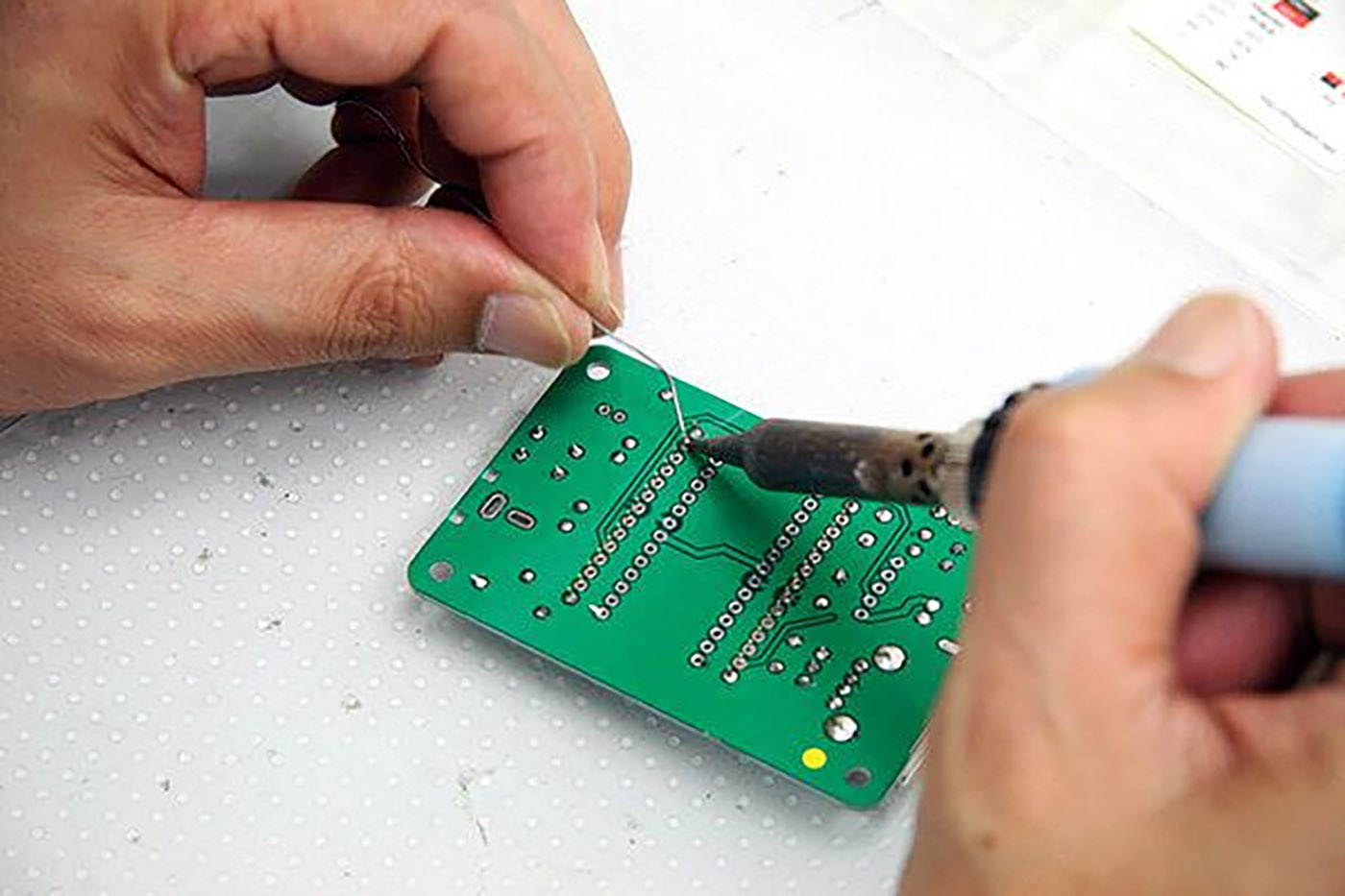

Xa i-soldering components kwi-PCB, zimbini ii-teknoloji eziphambili, nge-Hole Technology (THT) kunye ne-Surface Mount Technology (SMT).I-THT yayisetyenziswa kakhulu kwiisekethe ezindala ngaphandle kwe-SMT, kwaye ngoku isetyenziswa kuphela kwiisekethe zabangaqeqeshwanga nabangabaziyo.Inkqubo yokuthambisa ngomngxuma ibandakanya ukugrumba imingxuma kwi-PCB, ukufaka izinto ze-elektroniki kwi-PCB, kunye nokuthengisa icandelo elikhokelela kwiingcingo zobhedu kwelinye icala lebhodi.Le nkqubo yokuwelda iyabiza, iyacotha, inzima kwaye ayinako ukuzenzela.Ukongeza, amacandelo aneetheminali ezikhokelayo athande ukuba mkhulu, awenze angafaneleki kwiisekethe zale mihla zombane ezineemfuno zefomu ebalulekileyo.

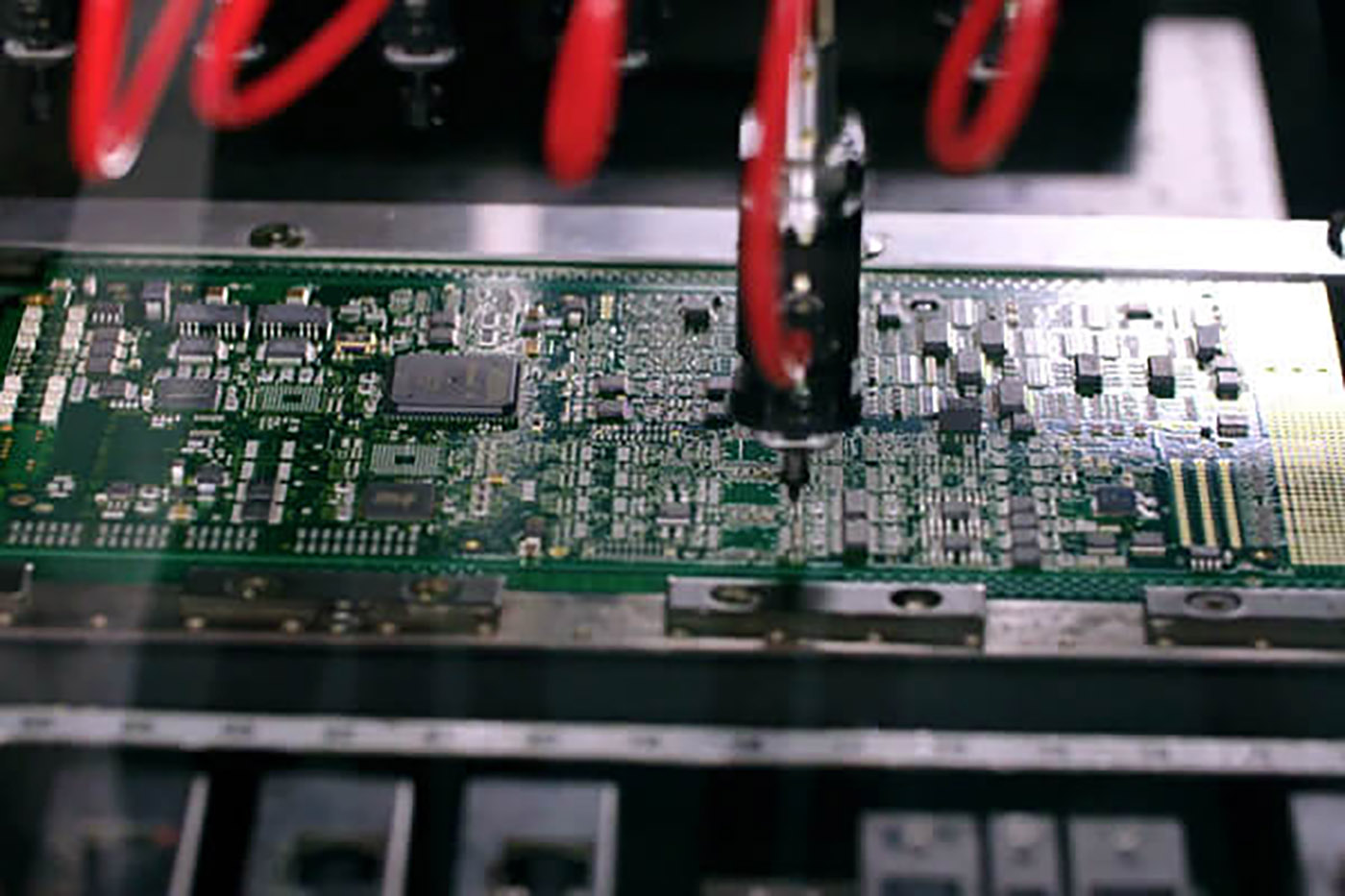

Namhlanje, ukusetyenzwa kwe-SMT kuphantse kwathatha indawo yeendlela zokuthengisa zemveli kwimveliso yePCB.Kwi-soldering ye-SMT, amacandelo abekwe ngokuthe ngqo kumphezulu we-PCB kunokuba ngokugrumba.Izixhobo zoMphezulu weMount ( SMD ) zinonyawo oluncinci kunezixhobo zeTHT eziqhelekileyo.Ngesi sizathu, inani elikhulu lamacandelo e-SMD linokupakishwa kwindawo encinci, ivumela ukuyilwa kwesekethe ye-elektroniki edibeneyo kunye nentsonkothileyo.Enye inzuzo enkulu ye-SMT yecandelo le-soldering kukuba inkqubo inokuzenzekelayo ngokupheleleyo, ukwandisa ukuchaneka, ukukhawuleza, ukusebenza kakuhle kunye nokuphumelela kweendleko.Namhlanje, i-SMT soldering ngoku yindlela yokudityaniswa kwePCB engagqibekanga.

Kutheni inkqubo ye-SMT kufuneka inikezelwe kwinkampani yobuchwephesha?

Akukho mathandabuzo ukuba i-SMT i-soldering component ineenzuzo ezininzi, kodwa inkqubo ikude kakhulu.Enyanisweni, ukuthengisela i-SMT yobuchwephesha yinkqubo enzima ebandakanya amanyathelo enkqubo ezininzi.Ukunikezelwa kobunzima benkqubo kunye nenqanaba lobuchule obufunekayo, umsebenzi we-SMT soldering kufuneka wenziwe ngabasebenzi abaqeqeshiweyo.

• Izixhobo ezikhethekileyo kunye noomatshini

• Ukuthengwa kwecandelo

• izakhono nobuchule

Izixhobo kunye noomatshini abafunekayo kwi-SMT soldering bahlala bebiza kakhulu.Kunokuba nzima kwi-novice ukuseka ibhubhoratri efanelekileyo kunye nazo zonke izixhobo eziyimfuneko kunye noomatshini njengoko kunokubiza imali eninzi.Nangona kunjalo, inkampani yokulungisa i-SMT efana nePinnacle inoseto olufanelekileyo kuzo zonke izixhobo eziyimfuneko.Ke ngoko, ukukhutshwa kwe-SMT kunokwenza ukuhamba komsebenzi kube lula, ngokuthe ngqo kwaye kungabizi kakhulu.

Ukongeza ekuboneleleni ngezixhobo kunye noomatshini, ukwazi kunye nokwazi kubaluleke kakhulu.Oomatshini abanamsebenzi ngaphandle kobuchule obufanelekileyo.I-soldering ye-SMT yinkqubo entsonkothileyo efuna ukuzinikela kunye nokuziqhelanisa nenkosi.Ke ngoko, kulunge ngakumbi ukushiya umsebenzi wokuhlanganisa kwiingcali kunokubuyisela ivili ngokwakho.Ukongeza, iinkampani ezinobuchwephesha bokuthengisa be-SMT zikwasebenza ngokukhethekileyo ekufumaneni izinto, ezivumela ukuba zifumane izinto ngokukhawuleza nangexabiso eliphantsi.

I-SMT component soldering market yayixabiswa kwi-USD 3.24 billion kwi-2016 kwaye kulindeleke ukuba ikhule kwi-8.9% ngexesha le-2017-2022.Imarike ye-SMT yimarike enkulu enamacandelo amaninzi emarike.Abaphulaphuli ekujoliswe kubo baquka abayili be-IC, ii-OEM, abavelisi beemveliso, amaziko e-R&D, abahlanganisi benkqubo kunye neefemu zokubonisana.

Ngenxa yokuba iibhodi zeesekethe eziprintiweyo ezichanekileyo zisetyenziswe kuzo zonke iindlela zobomi, akukho ntsimi engahambelani nobuchwepheshe be-SMT.Imimandla ekugxilwe kuyo ibandakanya abathengi bombane, unxibelelwano ngefowuni, i-aerospace kunye nokhuselo, iimoto, ubuchwephesha bezonyango kunye noshishino.

Ixesha lokuposa: Mar-29-2023