Kwiinkampani ezininzi zeemveliso ze-elektroniki ezincinci kunye neziphakathi, ukukhupha i-PCB patch processing yinto eqhelekileyo. Kodwa ngokuqhelekileyo, izityalo ezininzi zokuvelisa ngaphandle aziyi kukwenzela yonke into, okanye azikwazi ukuthatha indawo yabathengi ukuze baphucule ezinye izinto, ezifana nebhodi kunye nokuguquguquka kwemveliso, ukulungelelaniswa koyilo, ukulungelelanisa inxalenye, njl.

Ukuba ukuthengwa okanye iinjineli zeshishini zingenza ezi zinto zilandelayo ze-8 kakuhle ngaphambi kokuphosa iimfuno kunye nezixhobo zokuvelisa kwi-PCB i-patch processing factory, uninzi lweengxaki ezifunyenwe kwimveliso yamva kunye nokuveliswa kunokuphetshwa.

1. Fumana eyona sayizi yePCB yoyilo lwakho

Kwimveliso ye-PCB, iibhodi ezincinci zithetha iindleko eziphantsi, kodwa ukuyila kunokufuna iileya zangaphakathi ezingaphezulu, eziya kwandisa iindleko zakho. Iibhodi ezinkulu ziya kuba lula ukuzicwangcisa kwaye aziyi kufuna iileya zeempawu ezongezelelweyo, kodwa kuya kuba kubiza kakhulu ukwenziwa. Okokuqala, kufuneka uqwalasele indlela yokubala ubukhulu obufanelekileyo ngaphandle kokulahlekelwa iimpawu.

2. Chaza ubungakanani becandelo

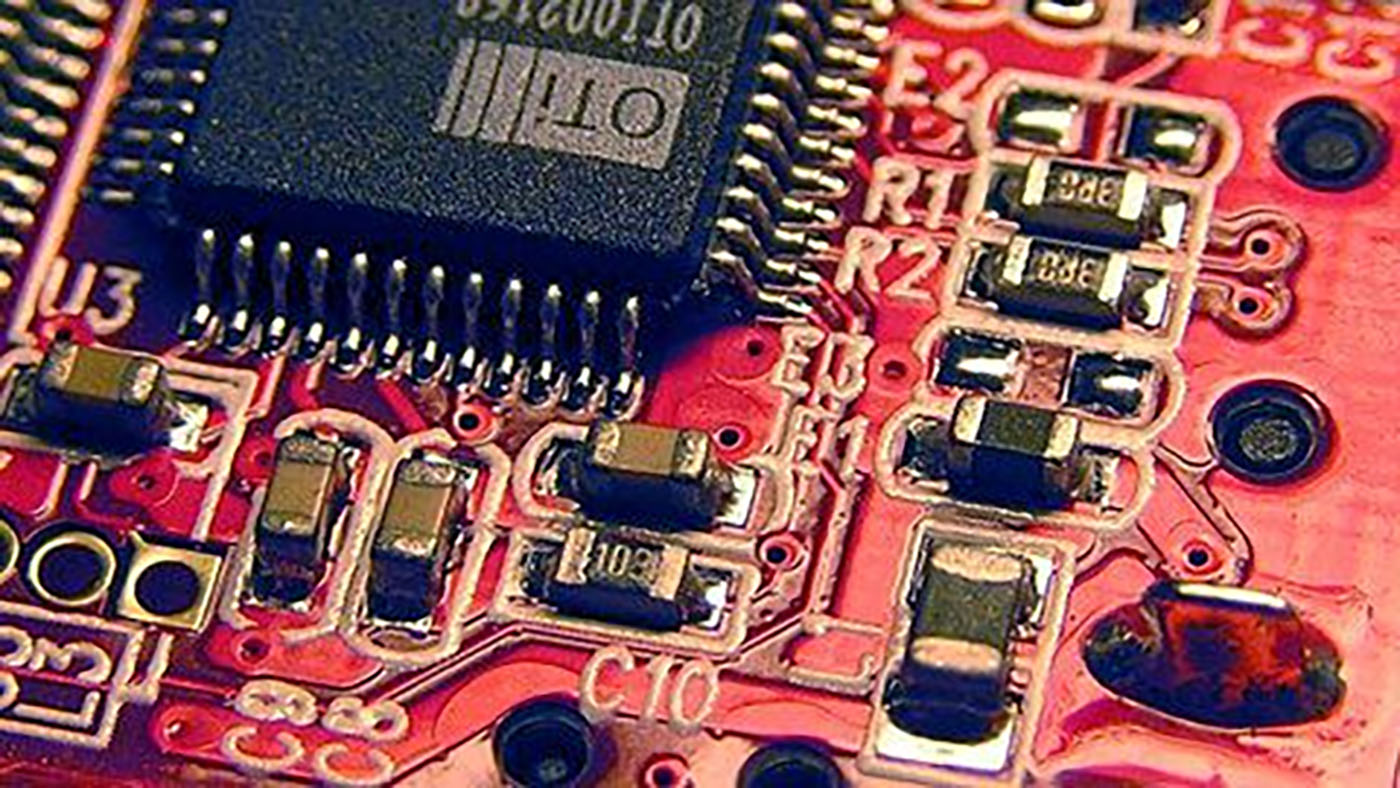

Unikezelo lwangaphandle PCB patch processing.jpg

Kumacandelo angenakwenziwa, ubungakanani obuqhelekileyo be-0603 bunokuba lolona khetho lungcono kwixabiso eliphantsi, elikwalingana nobukhulu obuqhelekileyo kwaye lilungele ukudityaniswa kwe-SMT. Izixhobo ze-0603 zikwalula ukuzihambisa kunye nenkonzo, kwaye musa ukuba ngumqobo njengezixhobo ezizezona zincinci.

Ngelixa i-Pinho ikwazi ukucubungula izixhobo ze-01005-ubungakanani, ayingabo bonke abahlanganisi abanokuyenza, kwaye iinxalenye ezincinci azibalulekanga.

3. Khangela iindawo eziphelelwe lixesha okanye ezintsha kakhulu

Amacandelo aphelelwe lixesha ngokucacileyo, oko akuyi kukuyekisa ukwenza i-PCBA, kodwa iya kuxinga kwinkqubo yendibano. Namhlanje, nangona kunjalo, amanye amalungu amatsha afumaneka kuphela kwi-ultra-miniature wafer BGA okanye kwiisayizi ezincinci ze-QFN. Jonga kwi-design yakho ye-PCBA kwaye uqiniseke ukuba utshintshe naziphi na iindawo eziphelelwe lixesha kunye nezingcono ezintsha.

Enye inqaku kukukhumbula ii-MLCC ozisebenzisayo, ngoku zifuna umjikelo omde wokuthenga.

Ngoku sinika abathengi uhlalutyo lwe-BOM olujonge phambili, qhagamshelana nathi ukuze ufunde ukuba unokukunceda njani ukuphepha umngcipheko kunye nokunciphisa uhlahlo lwabiwo-mali ukuya kwinqanaba elikhulu.

4. Qwalasela ezinye iindlela

Iindlela ezizezinye zisoloko zingumbono olungileyo, ngakumbi ukuba sele usebenzisa amanye amalungu omthombo omnye. Ukufumana indawo enye kuthetha ukuba uphulukene nolawulo kumaxabiso kunye namaxesha okuhanjiswa, ezinye iindlela ziya kukunceda ukuphephe oko.

5. Musa ukulibala ukutshabalalisa ubushushu xa usenza iibhodi zeesekethe eziprintiweyo

Amalungu amakhulu kakhulu kunye namalungu amancinci kakhulu angabangela iingxaki. Inxalenye enkulu isebenza kancinci njengendawo yokutshisa ubushushu kwaye inokonakalisa indawo encinci. Okufanayo kunokwenzeka ukuba i-foil yobhedu yangaphakathi idibanisa kwisiqingatha secandelo elincinci kodwa kungekhona esinye isiqingatha.

6. Qinisekisa ukuba inombolo yelungu kunye neempawu zepolarity ziyafundeka

Qinisekisa ukuba icacile ukuba yeyiphi i-silkscreen ehamba neyiphi indawo, kwaye iimpawu ze-polarity azikho mbaxa. Nika ingqalelo ekhethekileyo kumacandelo e-LED kuba ngamanye amaxesha abavelisi batshintshana ngeempawu ze-polarity phakathi kwe-anode kunye ne-cathode. Kwakhona, gcina iziphawuli kude ne-vias okanye naziphi na iipads.

7. Jonga uguqulelo lwefayile

Kuya kubakho iinguqulelo ezininzi zexeshana zoyilo lwePCB okanye i-BOM, qiniseka nje ukuba ezo osithumelela zona kukwenziwa kwe-PCB luhlaziyo lokugqibela.

8. Ukuba iindawo ezithile ziya kubonelelwa

Nceda uqinisekise ukuba uzilebhile kwaye uzipakishe ngokufanelekileyo, kubandakanywa ubungakanani kunye nenombolo yenxalenye ehambelanayo. Ulwazi olucacileyo olunikeziweyo luya kunceda abavelisi ukuba bagqibe ukuveliswa kunye nokuhlanganisa iibhodi zeesekethe eziprintiweyo ngokukhawuleza.

Ixesha lokuposa: Mar-29-2023